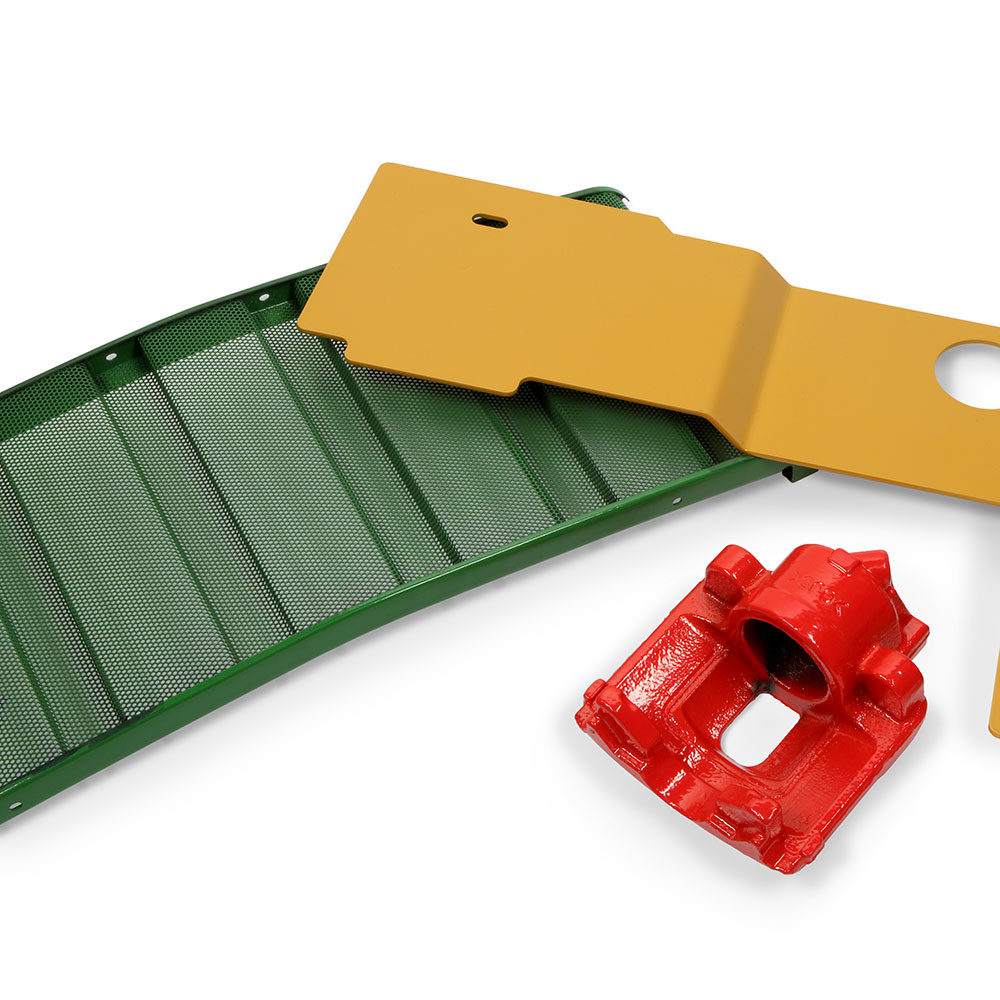

Powder Coat

Tougher than conventional paint

Powder coating is an organic coating that is applied as a free-flowing, dry powder. The main difference between conventional liquid paint and powder coating is that the powder coating does not require a solvent to keep the binder and filler parts in a liquid suspension form. Our thermoset polymer coatings are applied electrostatically and then cured under heat to allow the powder to flow and form a hard “skin” that is tougher than conventional paint. RMF meets a number of specifications calling for various polyester, polyurethane, polyester-epoxy, and straight epoxy polymers.

- Applications

- Coating ferrous metals such as stampings, castings, forgings as well as aluminum extrusions

- Uses include automotive/heavy truck components, industrial equipment, and household appliances

- Hundreds of colors and textures

- Parts of all sizes and shapes

- Can be applied as a single coating or applied over plating or over electrocoating

- Typical thickness of 50-100 microns of thickness

- Advantages

- Because powder coating does not have a liquid carrier, it can produce thicker coatings than conventional liquid coatings without running or sagging

- Produces minimal appearance differences between horizontally coated surfaces and vertically coated surfaces

- Environmentally friendly – no volatile organics

- Durable corrosion resistant coating

"*" indicates required fields

Contact Us

Roy Metal Finishing, located in Greenville, South Carolina, is the largest independent metal surface coater in the southeastern region of the US. Our core technologies are electroplating, e-coating and powder coating. We service the transportation, construction, agricultural, appliance and industrial markets.

RMF is a wholly-owned subsidiary of the Aalberts family of companies, which consists of over 150 companies and over 13,000 employees located throughout Europe, Asia and North America, all in pursuit of excellence through winning with people.Phone

(864) 277-0420

Corporate Campus

1515 Old Grove Rd

Piedmont, SC 29673